Components for

hydroelectric plants

Components for hydroelectric plants

For hydroelectric plants, our turbine shafts and Francis, Kaplan and Pelton turbine impellers, nozzles, blades, butterfly valves and sphere valves, forced ducts and distribution spirals are of great pride; our consolidated know-how and the use of cutting-edge technologies have allowed us to support the manufacturers of hydropower plants by offering solutions that are consistent with current programs in terms of reduced consumption and costs.

Components for hydroelectric plants

COMPONENTS FOR HYDRO TURBINES

We work and supply components for hydroelectric turbines, shafts, crates, and impellers, for all three different ways of exploiting waterpower, namely Francis, Kaplan, and Pelton turbines.

A hydroelectric turbine is a device that transforms the kinetic energy of water into mechanical energy; it is estimated that more than 90% of the kinetic energy of water is intercepted and transformed by this component.

A turbine is composed of two fundamental elements, a fixed part, the stator, and a rotating part, which is the rotor, the former to direct and regulate the flow of water, the latter that transfers the kinetic energy to the turbine shaft on which it is installed.

Depending on the type of rotor, water flow rate and elevation gain, three distinct types of hydroelectric turbine can be distinguished:

Francis, Pelton and Kaplan.

turbine

FRANCIS

Introduced in 1848, this type of turbine is centripetal flow, in which water enters radially, reaches the rotor through a spiral duct, and exits axially; for its geometry, it is used for medium differences in height – from 10 to 400 meters – and water range from 2 to 100 mq³/s.

For these high ranges of application, this turbine makes it the most used in different hydroelectric plants.

turbine

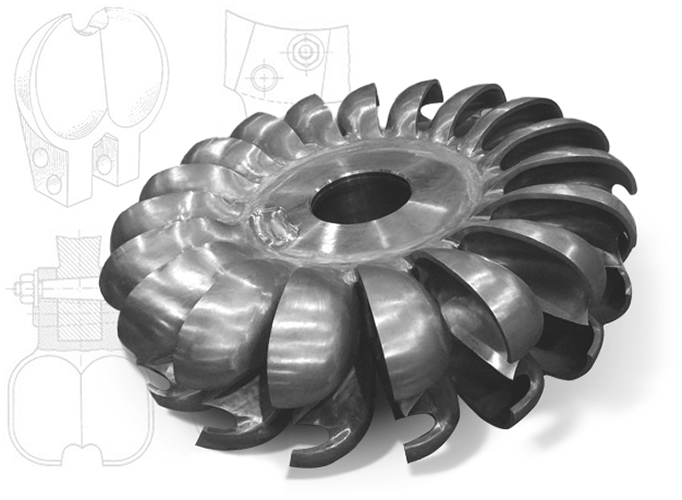

PELTON

Introduced in 1879, it presents a particular geometry, given that the element that captures the fluid presents a double-spoon form; its functioning might be compared to the one of a paddle wheel of windmills, given that the water is in fact conveyed into the forced duct, which has a nozzle toward the end that allows to increase the water speed by directing it.

The stream then exits the nozzle and hits the spoon blades of the rotor. This type of turbine is used for significant differences in height – between 300 and 1400 meters – and water range below 50 mq³/s, in order to achieve a higher speed.

turbine

KAPLAN

Introduced in 1913, it is an axial flow turbine, in which water enters and exits the rotor in an axial direction with respect to the axis of rotation of the rotor, making its functioning similar to the one of the propeller of a ship.

In terms of application, it makes up higher speeds when used for minor differences in height – up to 30 meters; the water range that can be processed, thanks to its axiality, can exceed 200 mq³/s. Kaplan turbines are made with swivel blades, as well as with a distributor, thus managing to direct the flow to the variation of the range in an optimal direction.

Its turbine case is shaped like a snail, as well, and a diffuser is installed at the drain.

For any info or quotation, please contact the sales department

GUARANTEED PRECISION AND QUALITY

DOWNLOAD THE PDF OF OUR MACHINES